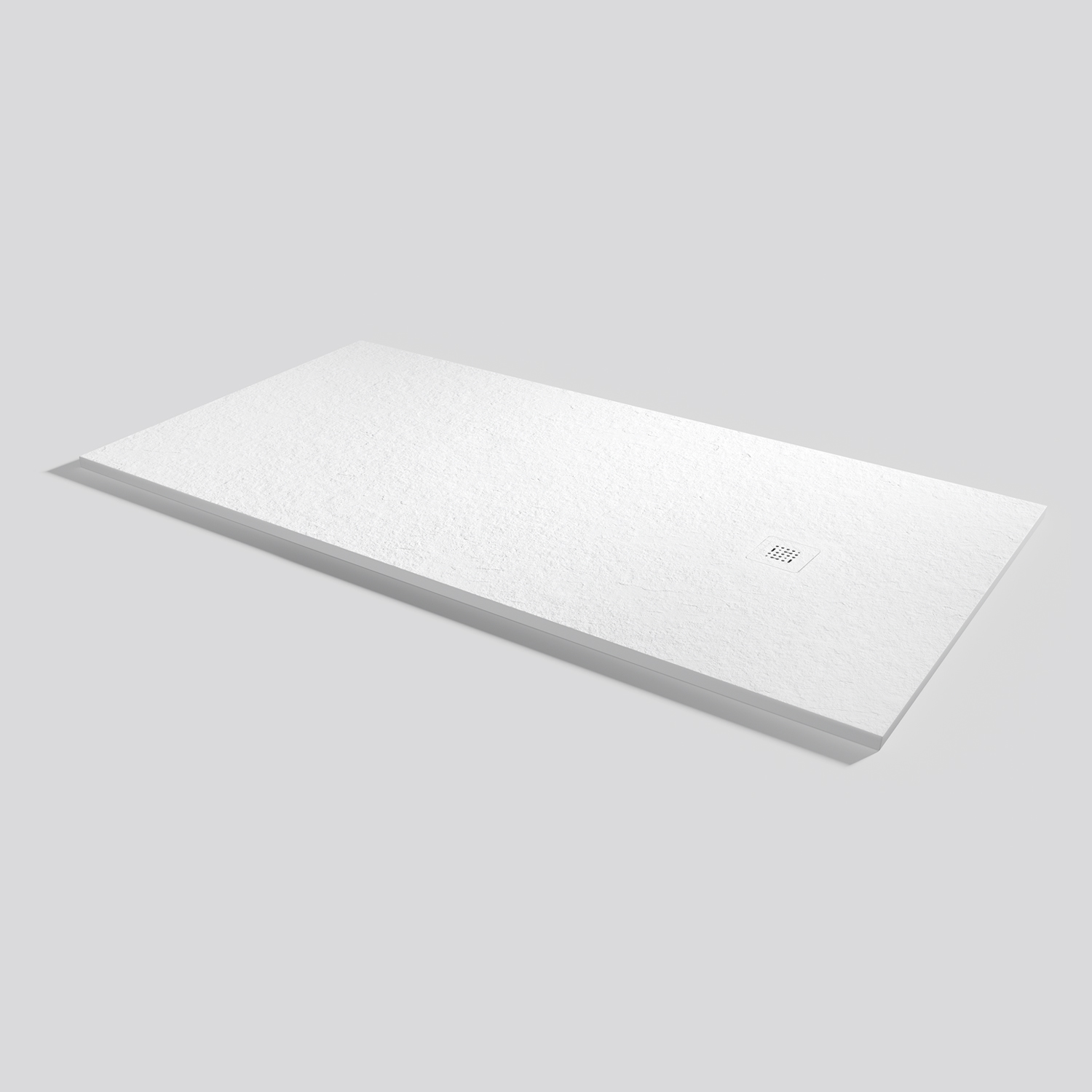

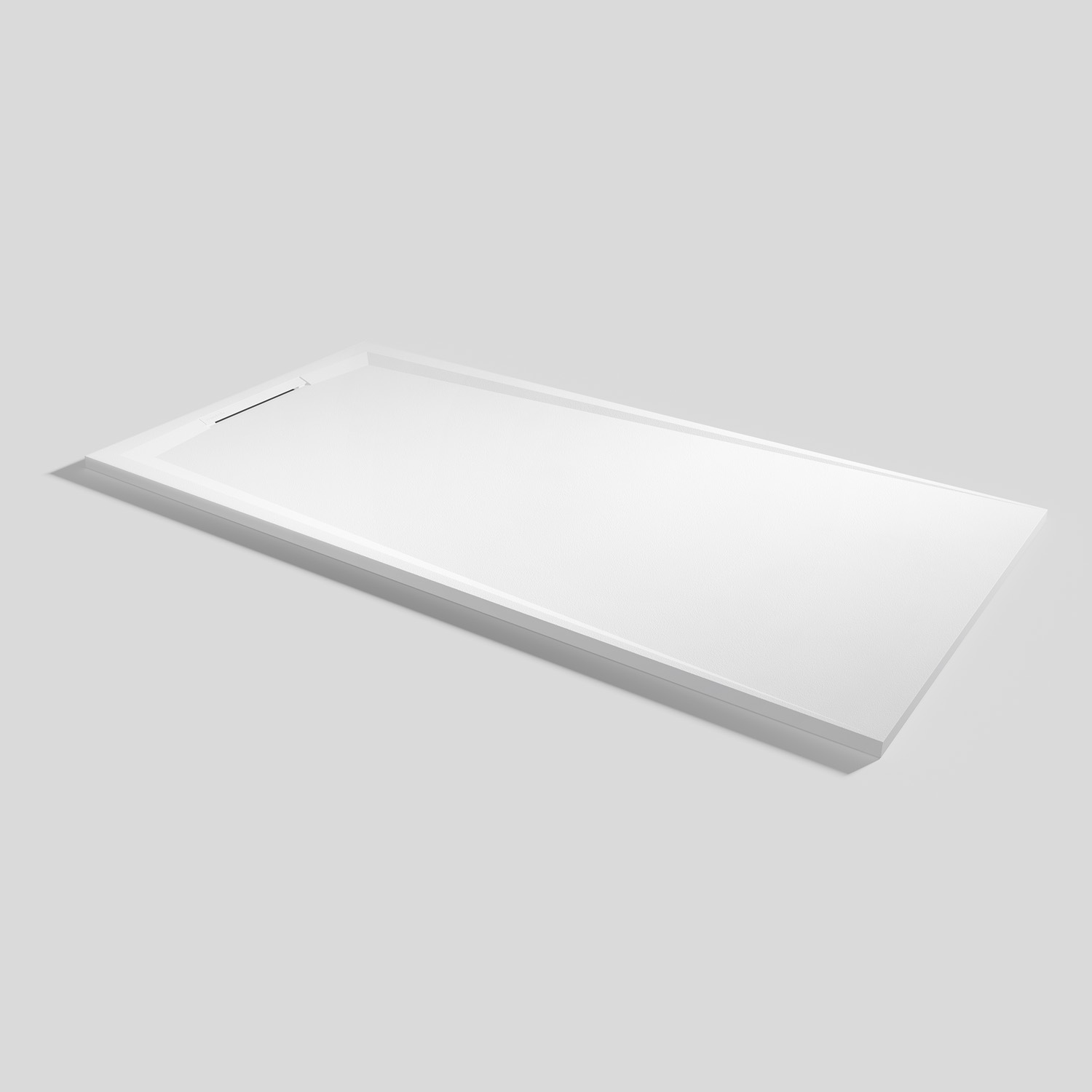

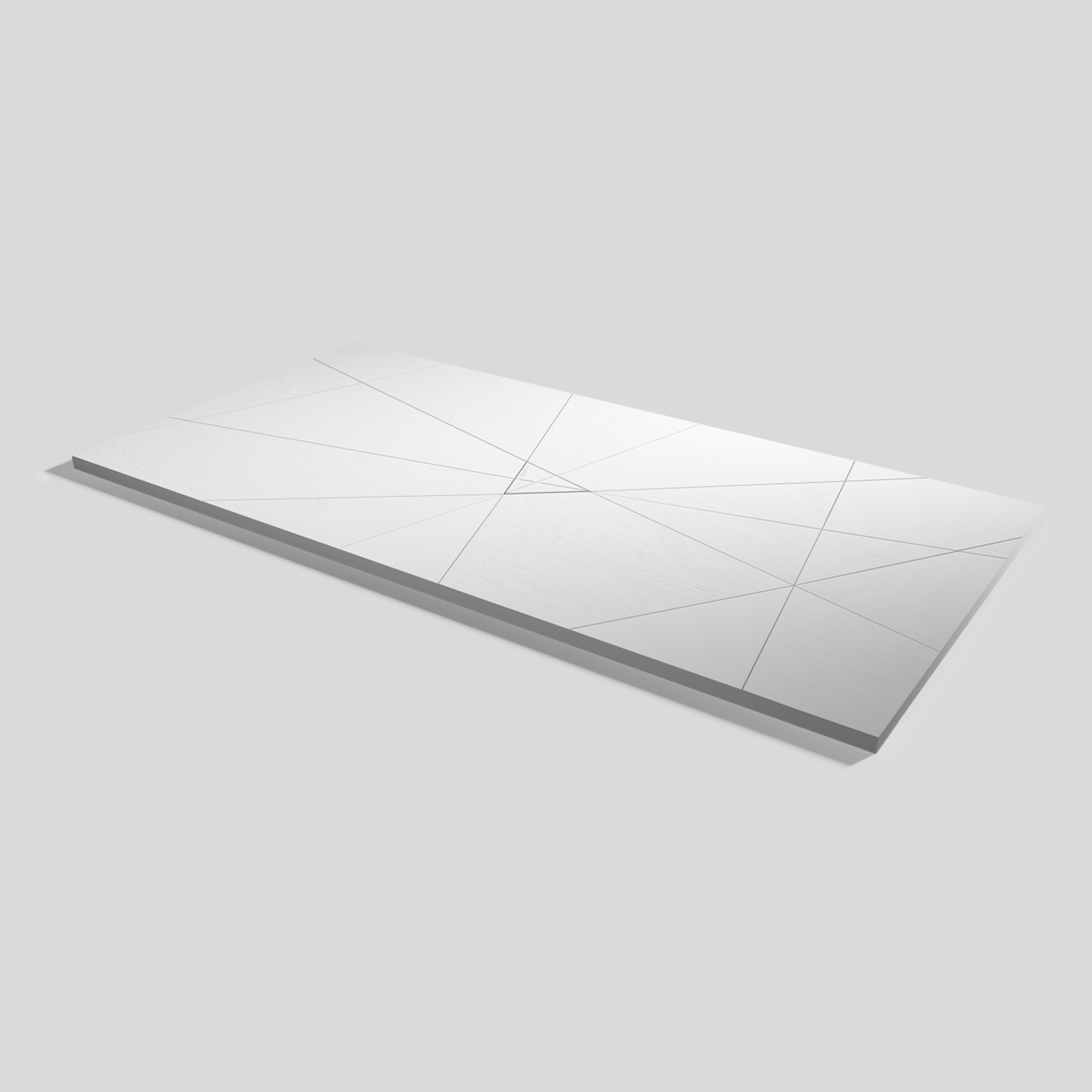

Founded more than 25 years ago, the Spanish bathroom product manufacturer has not stopped growing since then, with constant attention to product quality and reliably excellent service. Today, the company continues to adapt to the new demands of the market, which is why it has installed the largest automatic manufacturing line for shower trays in Europe at its facilities in Vall d’Uixò; the line is the largest of its kind in Europe with 7,500 square metres exclusively devoted to the manufacture of shower trays made of polyurethane resin with mineral filler. With this extension, Acquabella has increased its annual capacity by 150%, from 240,000 shower trays to 600,000 thanks to its two production lines.

The new line has great technological features that will speed up the production process and is based on an RFID system that tracks orders throughout the production process, all in a continuous chain that guarantees optimum results and better working conditions in the plant.

Acquabella has always been a standard-bearer for quality and innovation, and proof of this is the R&DI plant inaugurated in 2019, where the brand develops its designs. Two years on, Acquabella has decided to invest in a new shower tray line. With all these improvements Construplas, the company behind the Acquabella brand, now has three separate buildings, the 7,500 square metre building devoted to shower tray manufacture, another for worktops, panels and accessories, and a third unit that houses innovation and product development.

This investment can be expected to lead to significant improvements in delivery times, marking a step change in customer service and making Acquabella even more competitive in the market.